As drones become essential tools for industry productivity, selecting a high-performance, well-designed flight platform directly impacts operational efficiency and cost control. As a dedicated brand in the industrial UAV sector, KEEL with H drone frame has gained recognition for its ultra-long endurance and modular technology, proving its value in emergency rescue, inspections, logistics, and other applications.

Today, KEEL’s flight platforms support payload capacities ranging from 0 to 100kg, with ongoing internal tests for 160 to 300kg versions, expected to debut at the Shenzhen UAV Expo.

In this article, we analyze why the KEEL series insists on using the “H” frame structure. While the commonly seen X-frame offers flexibility, it often falls short in heavy-load operations and complex environments, revealing issues such as structural instability and limited payload space. The KEEL UAVs not only address these shortcomings but also provide satisfactory solutions to common concerns about H-frame designs, such as insufficient stress resistance, high energy consumption, and poor portability.

Balance as the Foundation, Strength as the Backbone

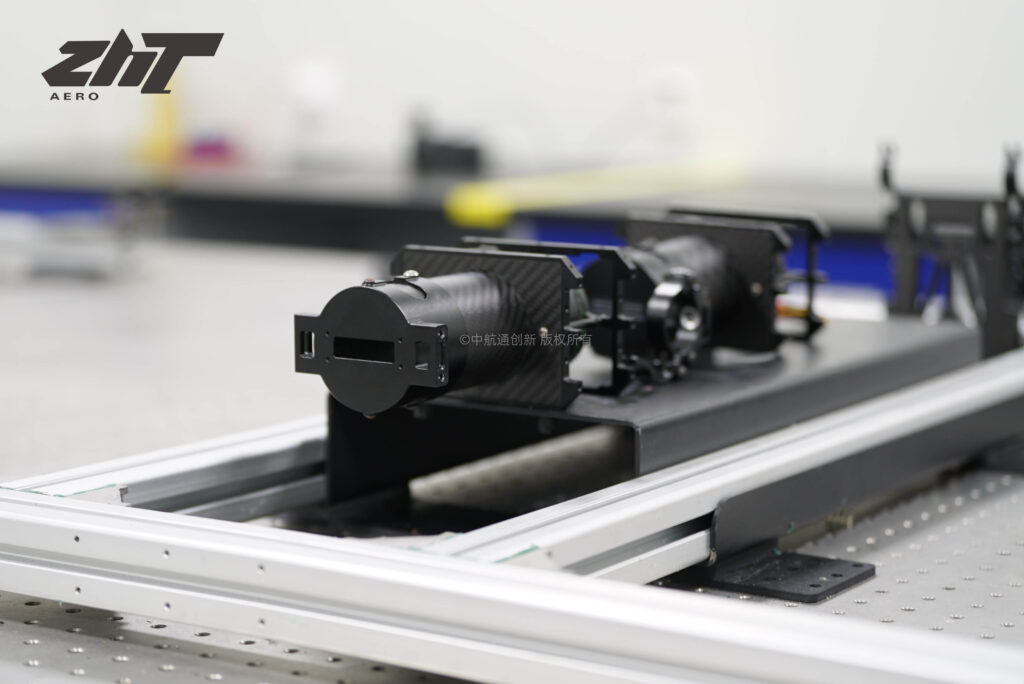

Precision-Tuned Structure: KEEL uses a proprietary alignment platform to ensure all structural components are precisely calibrated before entering the next assembly stage. The parallel front and rear arms, along with a long-axis structure, provide superior stability when facing external forces like high-speed flight or strong winds.

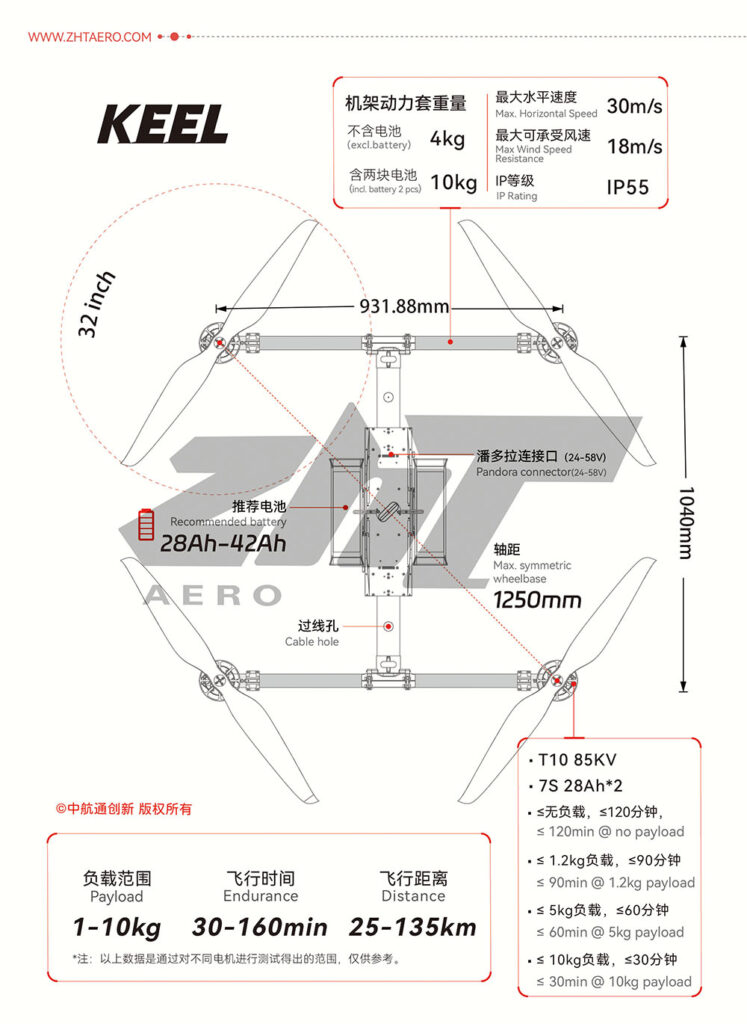

Compact and Lightweight Design: With a maximum symmetrical axis length of 1250mm, KEEL drone frame boasts a smaller size in the 10kg payload category. The frame itself weighs only 2.3kg, built from premium carbon fiber composites and aerospace-grade aluminum.

Reinforced Stress Areas: By implementing multi-layer cross-stacked carbon fiber in high-stress zones such as the arms and central cabin, KEEL achieves a lightweight yet rigid frame, reducing the weight by 20% and increasing strength by nearly three times compared to early prototypes.

Optimized Performance Balance: Structural reliability tests, aerodynamic efficiency optimizations, and flight control algorithm evaluations ensure KEEL strikes the perfect balance between durability and efficiency.

Scientifically Distributed Load

Centralized Weight Distribution: The H drone frame frame structure keeps the battery, gimbal, and sensors centralized, optimizing balance for heavy payloads. This results in a more stable flight attitude, significantly reducing motor power consumption and extending endurance.

Spacious Payload Area: The central space in the H-frame design allows for larger equipment integration, such as high-resolution cameras, multispectral sensors, or payload release mechanisms. Additionally, the modular landing gear accommodates different operational needs.

Quick Payload Swaps: KEEL features Pandora quick-release system, an innovative self-developed by ZHTAero, enabling rapid deployment and seamless payload transitions for various missions.

Rapid Response to Complex Commands

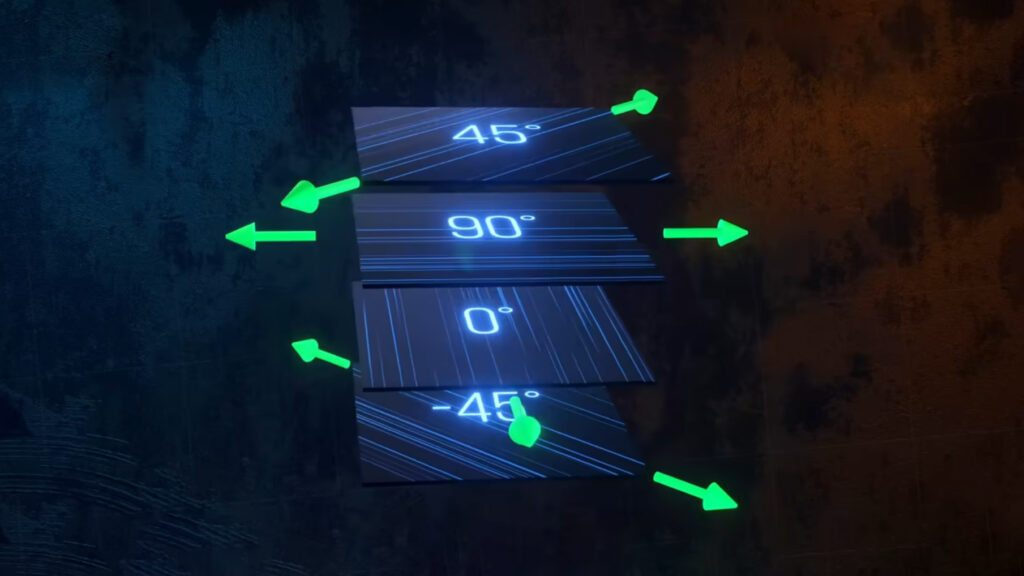

KEEL not only supports heavy payloads but also ensures agile performance. Through dynamic vibration damping strategies and advanced PID flight control algorithms, the drone effectively dissipates or counteracts vibrations, maintaining stability while reducing control latency. This enables:

- Significantly improved response speed

- Hover accuracy of ±0.1m (without RTK assistance)

- Overcoming traditional H-frame maneuverability limitations, making it ideal for large-scale emergency deliveries and logistics transportation.

Modular Design: 60-Second Assembly for Easy Deployment and Transport

Just like building with LEGO bricks, KEEL simplifies UAV assembly with a military-grade modular approach:

Dragon Claw Connectors + Plug-in Arms: No extra tools required—arms can be detached and reattached in just 20 seconds, tested for thousands of insertions with minimal wear, ensuring long-term reliability in frequent operations.

Quick-Release Propellers and Landing Gear: Enables easy maintenance and individual part replacements.

Compact Storage: Packing volume is only 0.171 cubic meters.

Multi-Payload Interface: Plug-and-play support for loudspeakers, LiDAR mapping, logistics pods, and more—swapping accessories is as easy as assembling LEGO.

Choosing KEEL’s H-frame structure means choosing more than just a drone—it means selecting efficiency, stability, and worry-free advanced productivity.

Innovation is Hard, Upholding Excellence is Even Harder

The KEEL series with H drone frame holds multiple utility model patents and design patents, each UAV embodying the dedication and expertise of our R&D team. Every patent serves as a shield protecting the brilliance of innovation.

Choosing KEEL’s H-frame structure means choosing more than just a drone—it means selecting efficiency, stability, and worry-free advanced productivity.